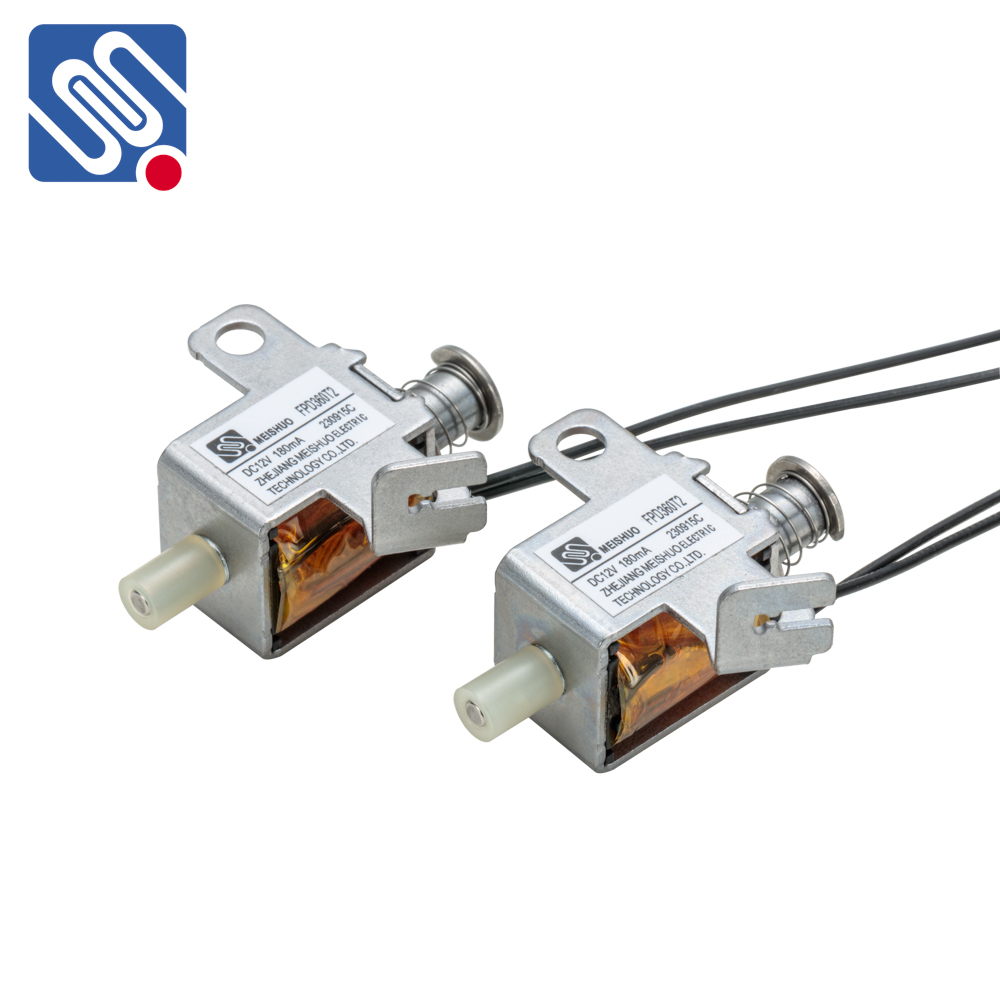

Mini solenoid valves, as the name suggests, are smaller versions of conventional solenoid valves that utilize electromagnetic force to control fluid flow. These compact devices are essential components in various industries, especially where space is limited, and efficiency is paramount. In this article, we explore the basic principles, applications, advantages, and selection criteria for mini solenoid valves.

Understanding the Basic Functionality A solenoid valve operates by using an electromagnet to control the flow of fluids (liquids or gases) through a valve. When the solenoid coil is energized, it creates a magnetic field that moves the valve’s internal mechanism (usually a plunger or diaphragm), opening or closing the fluid passage. Mini solenoid valves operate on the same principle but are designed to be smaller, offering a space-efficient solution without compromising performance. Mini solenoid valves typically come in two configurations: Normally Closed (NC) and Normally Open (NO). In the NC version, the valve is closed when no current is applied, and it opens when electricity is applied. Conversely, the NO version remains open when there is no current and closes when energized.