When it comes to industries dealing with volatile substances or operating in hazardous environments, safety and reliability are of utmost importance. One of the key components used to ensure these standards are met is the explosion-proof electric butterfly valve. These specialized valves play a crucial role in controlling fluid flow while minimizing the risks of sparks, electrical failures, or potential explosions. As a result, selecting the right manufacturer for explosion-proof electric butterfly valves is essential for industries to maintain safe operations.

What is an Explosion-proof Electric Butterfly Valve?

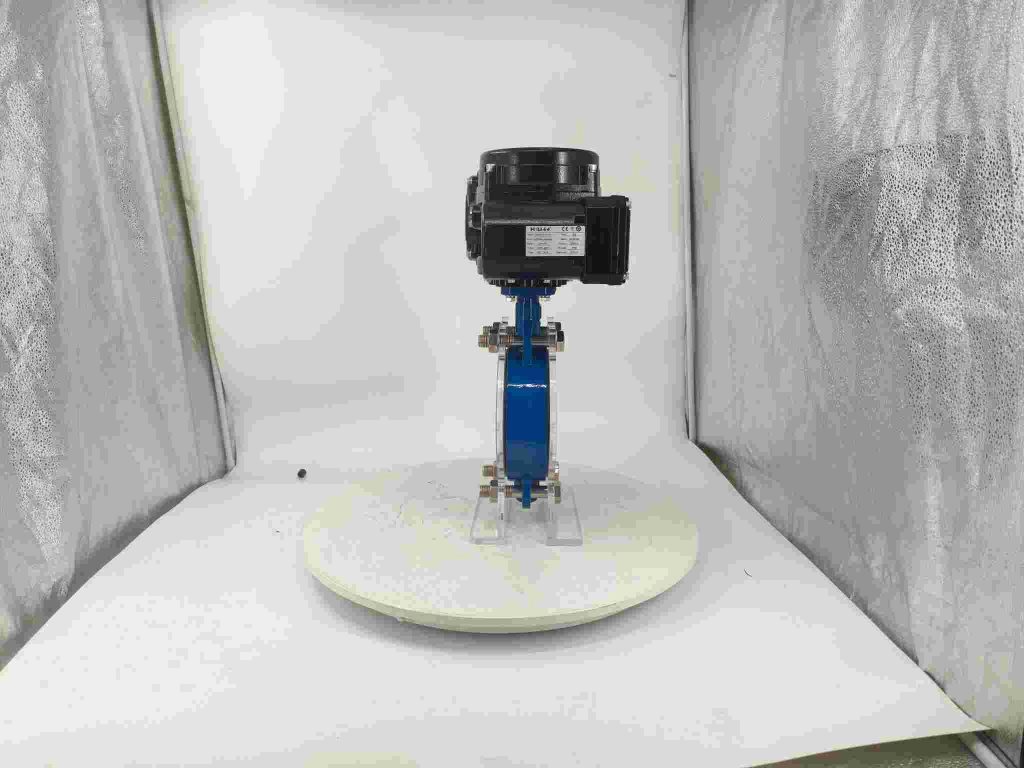

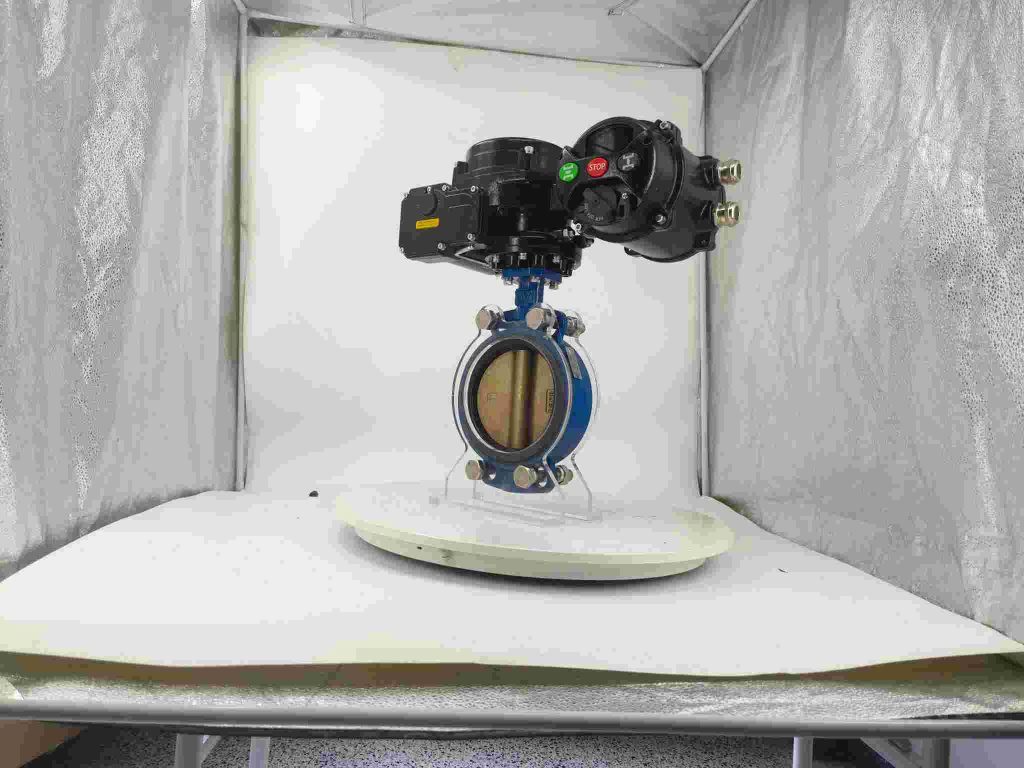

An explosion-proof electric butterfly valve is a type of valve that combines the features of a butterfly valve with electrical actuation. It is designed for use in environments where explosive gases, vapors, or dust are present, such as chemical processing plants, oil refineries, power plants, and mining operations. The explosion-proof design ensures that any potential electrical faults within the valve will not ignite hazardous materials in the surrounding atmosphere. The valve’s “butterfly” design refers to a rotating disk, which is used to control the flow of fluids or gases within a pipeline. When the actuator, which is powered by electricity, turns the disk, the flow is either opened or closed, depending on the operational requirements. What sets explosion-proof electric butterfly valves apart is the fact that they are built with protective measures that shield the valve from electrical malfunctions that could cause dangerous sparks or fires in potentially explosive environments.