In industrial processes, safety and efficiency are paramount. One critical component that plays a significant role in achieving these objectives is the explosion-proof electric butterfly valve. These valves are designed to control the flow of liquids or gases in various systems while preventing the risk of ignition in potentially hazardous environments. This article delves into the key features, applications, and advantages of explosion-proof electric butterfly valves in industrial settings.

What is an Explosion-proof Electric Butterfly Valve?

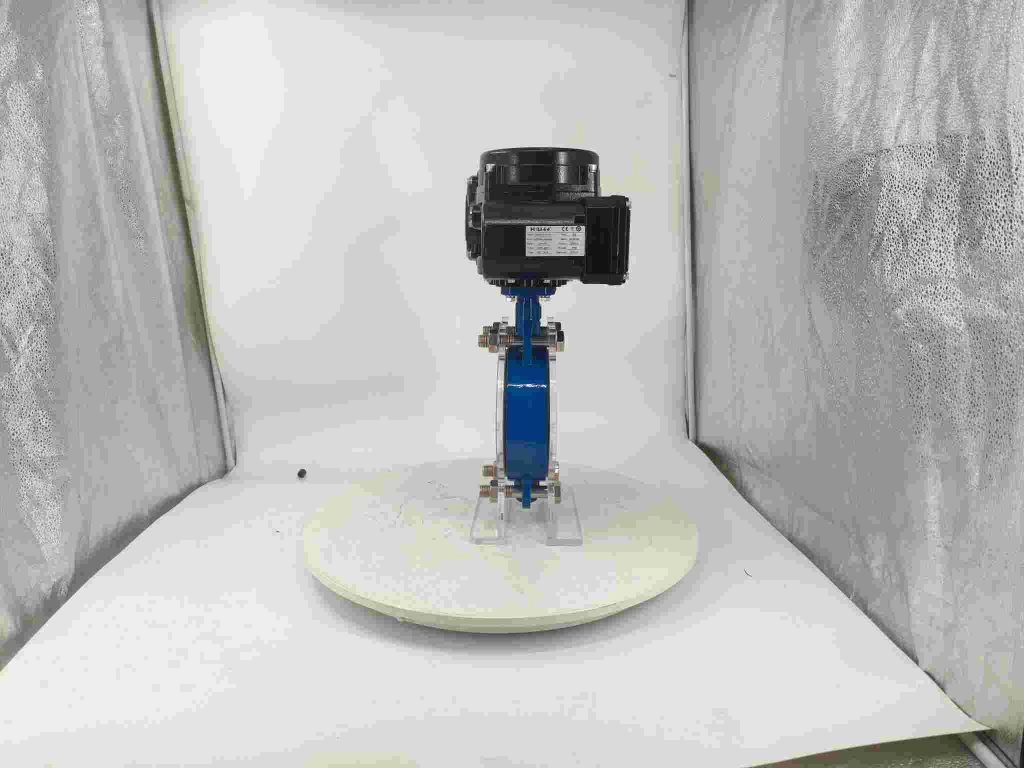

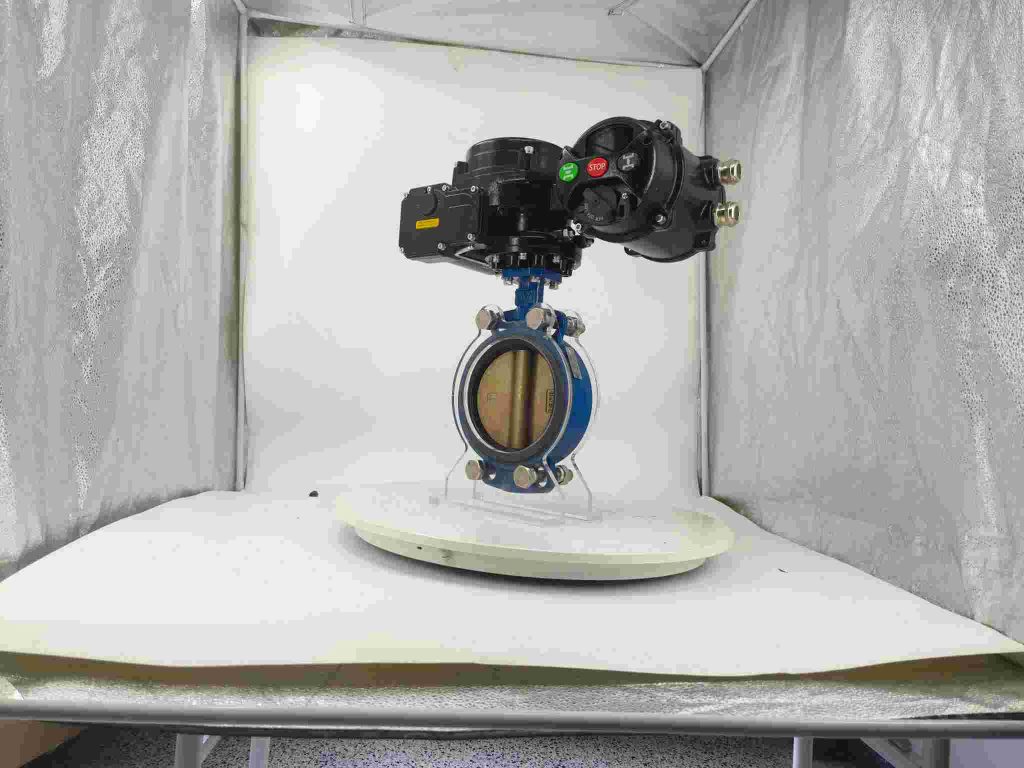

An explosion-proof electric butterfly valve combines the functionality of a butterfly valve with the added safety feature of explosion-proof technology. Butterfly valves are widely used to regulate the flow of fluids through pipes by using a rotating disc. When the valve is actuated, the disc either opens or closes, controlling the flow. The electric actuation provides precise control, allowing for automated operation and remote monitoring. The explosion-proof designation means that these valves are engineered to prevent any internal sparks or heat generated by the electric actuator from igniting the surrounding atmosphere. This is especially crucial in industries dealing with volatile chemicals, flammable gases, or combustible dusts, where even a small spark can lead to catastrophic explosions or fires.