Explosion-proof electric butterfly valves are crucial components in industries where volatile substances are handled. Their primary function is to regulate the flow of gases, liquids, and other materials while ensuring safety in environments that pose explosion risks. As the demand for explosion-proof solutions continues to grow, the role of manufacturers in this sector becomes increasingly significant. In this article, we explore the importance of explosion-proof electric butterfly valves, key factors to consider when choosing a manufacturer, and how industry leaders are shaping the future of industrial safety.

The Importance of Explosion-proof Electric Butterfly Valves

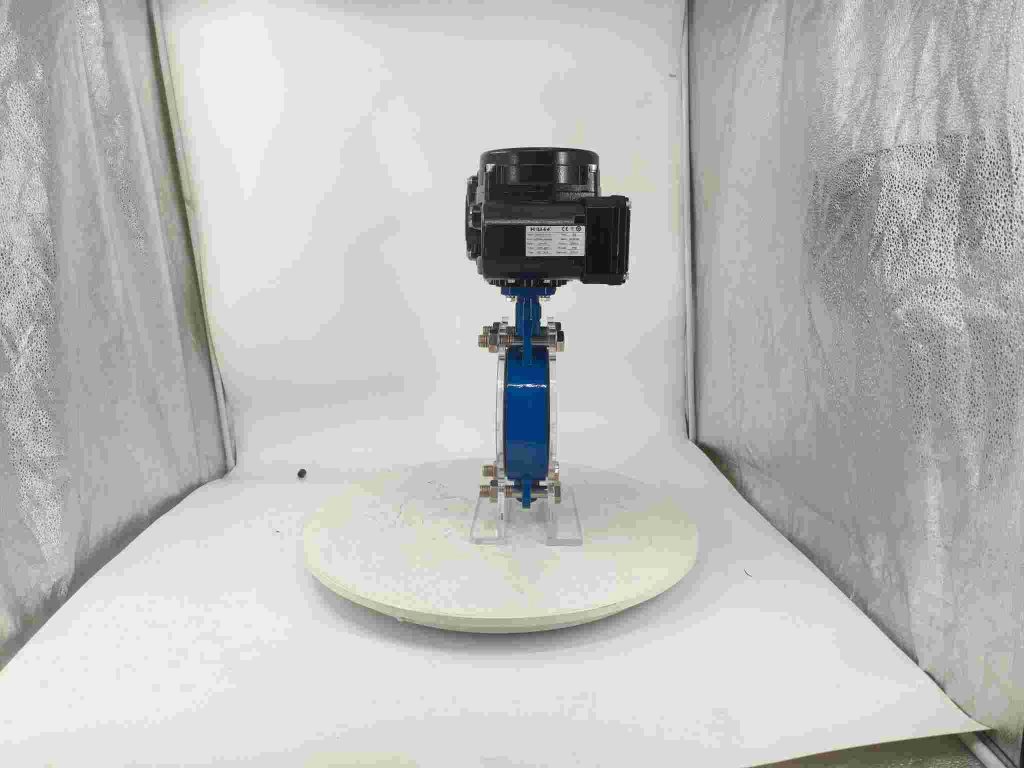

Explosion-proof electric butterfly valves are widely used in industries such as oil and gas, chemical manufacturing, pharmaceuticals, and mining, where equipment must withstand hazardous conditions. These valves are designed to prevent sparks, overheating, and other electrical malfunctions that could trigger explosions in environments where flammable or explosive substances are present. The electric butterfly valve consists of a disc (or “butterfly”) that rotates to control the flow of material. The valve is actuated by an electric motor, making it an efficient choice for automation in industrial systems. When equipped with explosion-proof features, the valve is capable of operating safely within explosive atmospheres. These valves are designed to meet stringent safety standards, including ATEX (for Europe) and IECEx (for international use), ensuring they meet the required protection levels.

Leave a Reply