Mini solenoid valves, often characterized by their compact size and efficient operation, have become an essential component in various industries, from automation systems to medical devices. These valves offer precise control over fluid flow, whether it is gas, liquid, or steam, and are particularly beneficial in situations where space is limited, or small flow rates are required. This article delves into the design, features, applications, and advantages of mini solenoid valves, showcasing their versatility and importance in modern engineering.

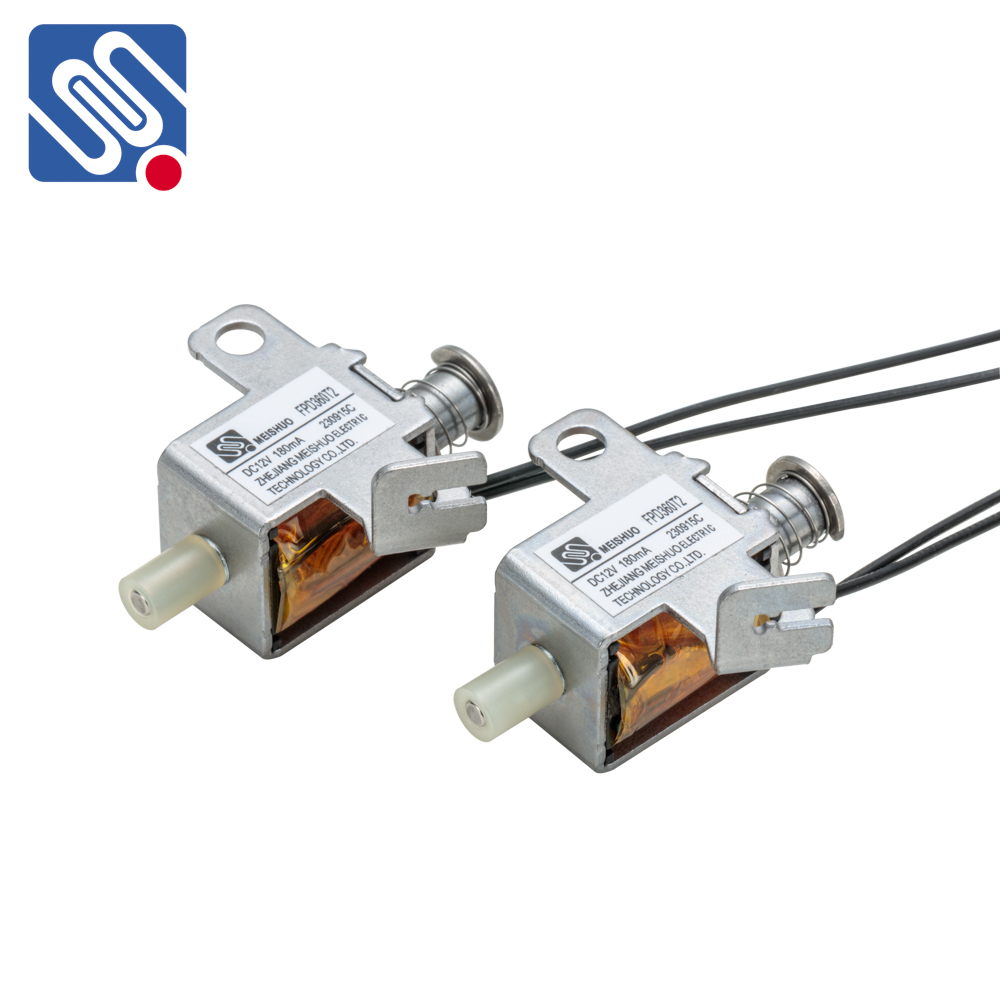

Introduction to Mini Solenoid Valves A mini solenoid valve is an electromechanical device used to control the flow of fluids in a pipeline or system. The valve consists of a coil, plunger, and spring, which, when electrically activated, either opens or closes the valve to allow or block the passage of fluid. The small size of these valves makes them ideal for applications where space constraints are a concern, such as in small automation systems, medical devices, and precision instruments. Design and Working Principle The design of a mini solenoid valve is based on the basic principle of electromagnetism. When electrical current passes through the solenoid coil, it generates a magnetic field that moves a plunger within the valve body. This movement either opens or closes the valve, depending on the configuration of the valve. The compact design of these valves allows for seamless integration into small devices or systems without sacrificing performance.