A Long Service Life Solenoid Valve is a critical component used in various industrial automation systems, offering extended reliability, durability, and performance. As industries continue to demand higher efficiency and cost-effectiveness, the role of solenoid valves with extended service life has become increasingly important. This article explores the features, advantages, and applications of Long Service Life Solenoid Valves, focusing on how they can significantly improve industrial processes while reducing maintenance costs and downtime.

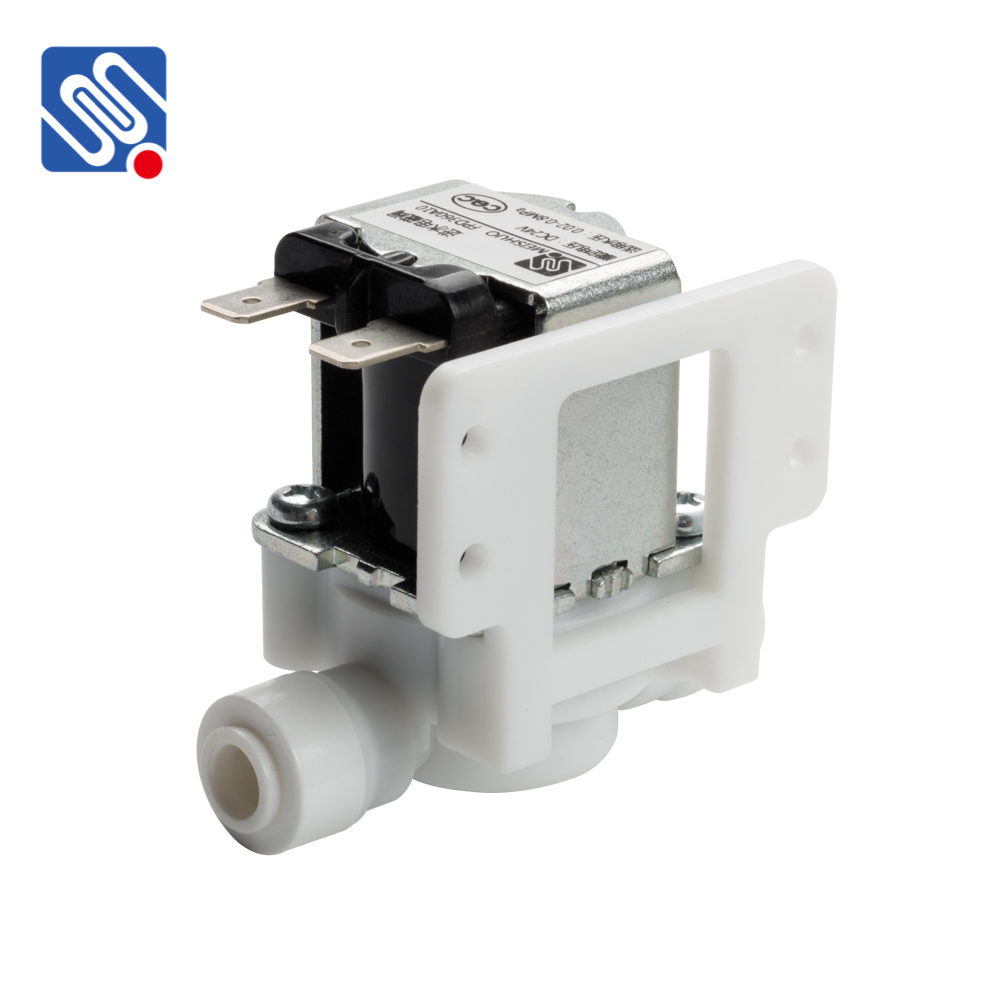

Introduction Solenoid valves are electrically operated valves that control the flow of liquids or gases within a system. The working principle behind these valves is relatively simple: an electric current energizes a solenoid coil, creating a magnetic field that moves a plunger or armature, which opens or closes the valve. However, despite their simple design, solenoid valves are crucial for many systems, such as HVAC, water treatment, manufacturing, and medical equipment, requiring high precision and reliability. A Long Service Life Solenoid Valve, as the name suggests, is designed to last longer than typical solenoid valves. They are engineered to withstand rigorous operating conditions, reducing the need for frequent replacements or maintenance. These valves are particularly beneficial for applications that involve high-frequency switching or operate in harsh environments, where reliability is paramount.