In industries where safety and efficiency are paramount, the demand for reliable components such as valves cannot be overstated. Among these, explosion-proof electric butterfly valves stand out for their unique ability to manage flow control in hazardous environments. As a result, the role of explosion-proof electric butterfly valve manufacturers has become increasingly critical, not only in terms of product quality but also in ensuring safety standards and compliance.

Understanding Explosion-Proof Electric Butterfly Valves

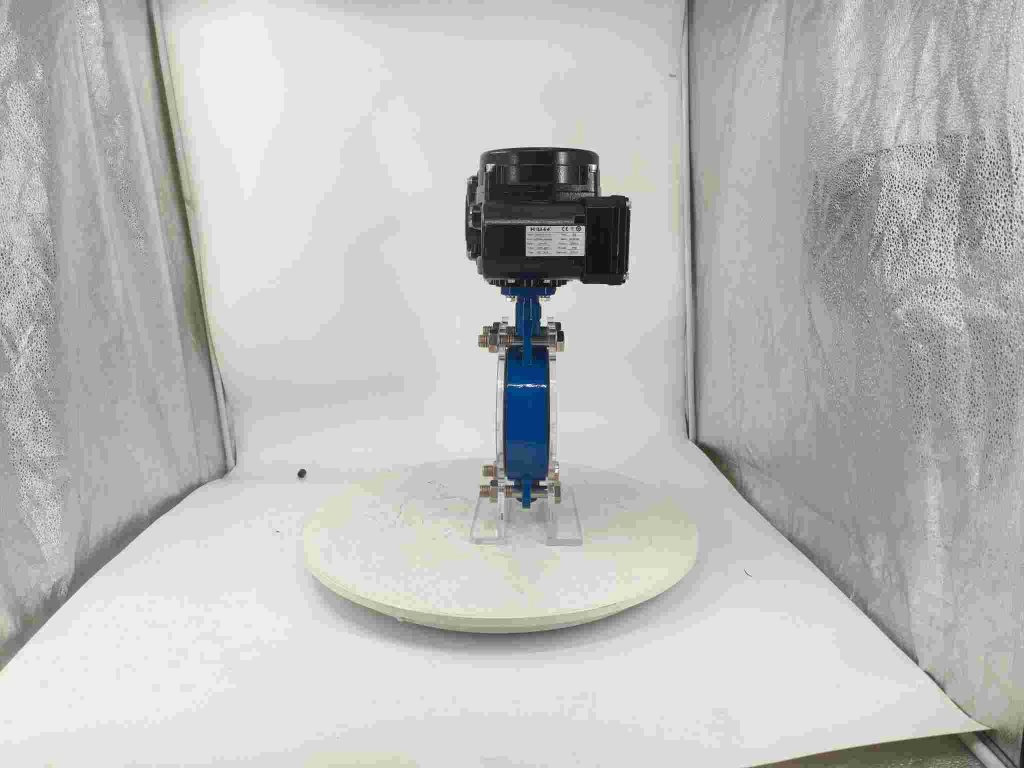

Explosion-proof electric butterfly valves are designed to regulate the flow of liquids and gases in environments that may be susceptible to explosions, such as petrochemical plants, gas distribution facilities, and various manufacturing plants. These valves incorporate a robust design to prevent ignition and mitigate risks associated with volatile substances. The electric actuation provides precise control, allowing for rapid response times in operational processes. The structure of a butterfly valve features a circular disc that rotates within the pipe to open or close the flow. When actuated electronically, these valves can be remotely controlled, making them ideal for automation in modern industrial applications. The explosion-proof aspect means that these valves are constructed from materials that can withstand external explosive forces, often equipped with protective housing and seals to prevent the ingress of ignitable substances.